Emial Us :

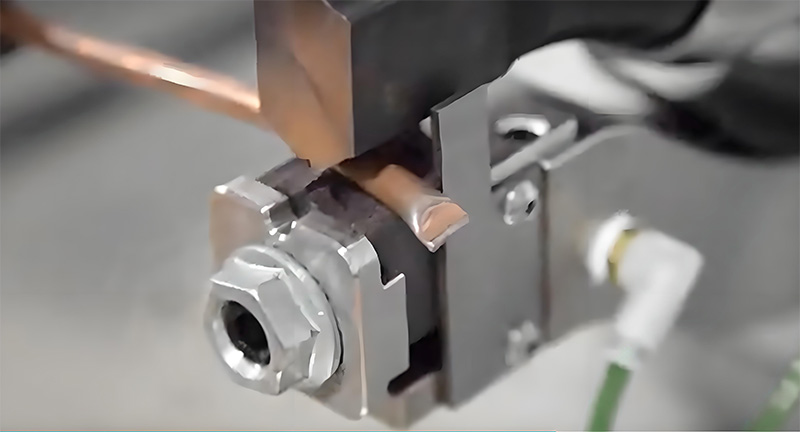

hongce@iectester.comUltrasonic welding machines use ultrasonic vibrations to generate heat, without the use of adhesives or solvents, to enable copper tubes to be seamlessly fused to achieve the purpose of sealing.

Item No :

HH-CH-308Order(MOQ) :

1 SetPayment :

T/T,L/CProduct Origin :

ChinaColor :

Customizable colorsShipping Port :

Guangzhou PortLead Time :

30 working daysPrice :

NegotiatableThe ultrasonic copper pipe sealing machine can complete the two processes of welding and cutting copper pipes or aluminum pipes at the same time. It is easy to operate, ensures no air leakage after welding, and has low equipment maintenance and mold costs. This device has been used in air conditioning, HVAC systems, refrigerators, and capillary bulb thermometer industries for 10 years. In the refrigerator industry, ultrasonic technology solves problems such as being labor-intensive and poor working conditions. Compared with the fire welding process, the ultrasonic welding process can save 60% labor costs.

|

Model |

HH-CH-308 |

|

Ultrasonic generator maximum output power |

3000W MAX |

|

Ultrasonic frequency |

20KHz |

|

Power supply |

220-240V/ 50Hz |

|

Air supply source |

≥0.65MPa |

|

Welding current |

16A(max) |

|

Copper tube diameter |

2mm-12mm |

|

Copper tube wall thickness |

1.0mm (max) |

|

Control system |

Power module/integrated P controls 10.1inches touch display interface;PLC |

|

Size |

L350mm*W450mm*H135mm(Chassis part)3.5Kgz L510mm* W265mm*H235mm(Mechanical part)11Kg |

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)