Emial Us :

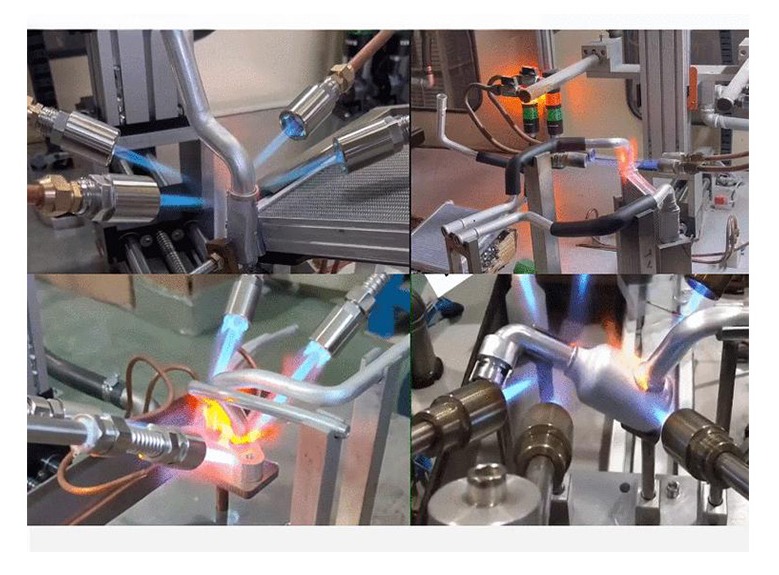

hongce@iectester.comThe Four-Way Valve Automatic Welding Machine is a specialized piece of equipment designed for the welding of four-way valve components within the air conditioning and refrigeration industry. This machine ensuring high efficiency, stability, and intelligence in its welding processes.

Item No :

HH-SH-303Order(MOQ) :

1 setPayment :

T/T,L/CProduct Origin :

ChinaColor :

Customizable colorsShipping Port :

Guangzhou PortLead Time :

30 working daysPrice :

NegotiatableFour-Way Valve Automatic Welding Machine

High Automation Level: The welding machine is equipped with an automated turntable that facilitates seamless workpiece movement from one station to another. Operators simply load the four-way valve onto the fixture, press the start button, and the machine takes care of the rest, including copper pipe installation, welding, cooling, and unloading.

Precision Welding: The machine accurately controls the wire speed, flame, and gas flow to ensure precise welding temperatures and the formation of a uniform solder fusing pool. This results in consistent welding quality with no false soldering or blackened oxide layers.

Versatile and Programmable: The welding process can be programmed according to specific production requirements, allowing for flexibility in handling different workpiece specifications and welding patterns.

Comprehensive Safety Measures: Equipped with advanced cooling systems, including air-cooling and water-cooling, the machine ensures the safe and efficient cooling of welded workpieces. Additionally, the use of stainless steel components and rust-treated surfaces further enhances durability and safety.

Main Technical Parameters:

Workpiece Requirements: The machine is designed for four-way valves with clean surfaces, no obvious oxide layers, and uniform specifications. The tolerance of the welding position after positioning the connection point should not exceed 1mm.

Welding Wire: Standard wire coil with BcuP-6 solder, wire diameter ranging from 1.2 to 1.5mm, and each coil weighing less than 10Kg.

Production Rhythm: Customizable based on specific production needs.

Wire Feeding Mechanism: Set outside the turntable, it automatically delivers welding wire to the welding workpiece.

Cooling Device: Equipped with both air-cooling and water-cooling systems to ensure efficient cooling of the workpiece during and after welding.

Performance Indicators:

Welding Effect: The solder flows evenly, resulting in a full molten pool with no defects such as false soldering or oxidized layers.

Consistency: The machine ensures stable and consistent welding quality across all welded workpieces.

Efficiency: Automated processes significantly reduce manual intervention, leading to increased production efficiency and reduced downtime.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)