Emial Us :

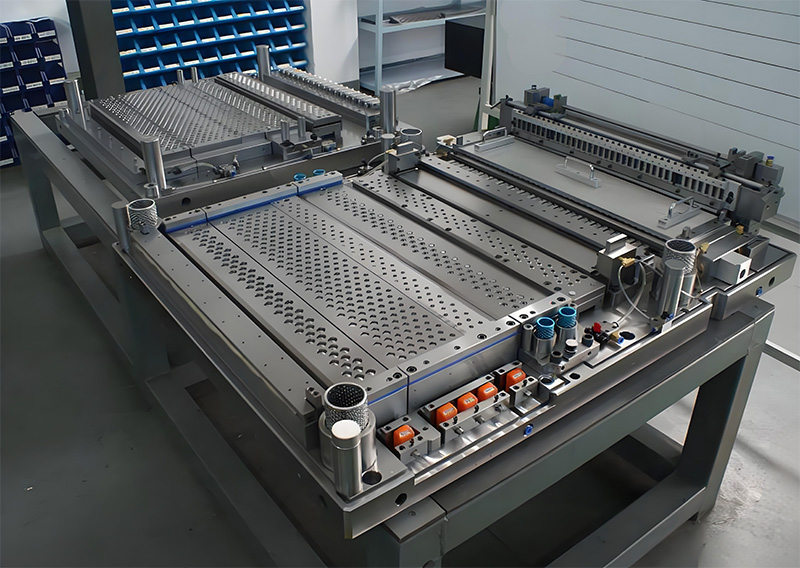

hongce@iectester.comThe HH series open fin punch is a special production line for fin production in the refrigeration industry. It consists of a high-speed precision punch, a discharge rack through the oil tank, a pulling device (single and double jumps), a suction rack, a collecting rack, an electrical system, Composition of pneumatic system.

Item No :

HH-CP-3045/HH-CP-3065/HH-CP-3085Order(MOQ) :

1 setPayment :

T/T,L/CProduct Origin :

ChinaColor :

Customizable colorsShipping Port :

Guangzhou PortLead Time :

30 working daysPrice :

NegotiatableThe open fin punching machine is specially designed for efficient, large-scale and high-precision fin production in the refrigeration industry to meet the strict requirements of refrigeration equipment manufacturers for fins.

The host speed is controlled by frequency conversion

The host has hydraulic overload function

Use human-machine interface and PLC and rotary encoder electrical centralized control system to ensure reliable execution of various functions of the automatic production line.

|

|

Item |

HH-CP-3045 |

||||

|

KW |

Capacity |

450 |

||||

|

spm |

Slide stroke length |

40 |

50 |

60 |

70 |

80 |

|

mm |

Press speed |

120-200 |

120-180 |

120-160 |

100-120 |

100-120 |

|

mm |

Die height |

210-270 |

205-265 |

200-260 |

195-255 |

190-250 |

|

mm |

Throat depth |

330 |

||||

|

mm |

Bottom of slide size |

530 x 340 |

||||

|

mm |

Bolster size |

850 x 660 |

||||

|

mm |

Height of collecting |

600 |

||||

|

mm |

Length of collecting |

1200/1500/2000 |

||||

|

mm |

Width of aluminum(max) |

330 |

||||

|

mm |

ID of aluminum |

Φ75/Φ150 |

||||

|

mm |

OD of aluminum |

Φ850 |

||||

|

KW |

Main motor |

5.5 |

||||

|

|

Supply voltage |

AC380V,50HZ,Three-phase five-wire system |

||||

|

|

|

|

|

|

|

|

|

|

Item |

HH-CP-3065 |

||||

|

KW |

Capacity |

650 |

||||

|

spm |

Slide stroke length |

40 |

50 |

60 |

70 |

80 |

|

mm |

Press speed |

120-200 |

120-180 |

120-160 |

100-120 |

100-120 |

|

mm |

Die height |

210-290 |

205-285 |

205-280 |

200-275 |

195-270 |

|

mm |

Throat depth |

330 |

||||

|

mm |

Bottom of slide size |

590 x 400 |

||||

|

mm |

Bolster size |

900 x 660 |

||||

|

mm |

Height of collecting |

600 |

||||

|

mm |

Length of collecting |

1200/1500/2000 |

||||

|

mm |

Width of aluminum(max) |

330 |

||||

|

mm |

ID of aluminum |

Φ75/Φ150 |

||||

|

mm |

OD of aluminum |

Φ850 |

||||

|

KW |

Main motor |

5.5 |

||||

|

|

Supply voltage |

AC380V,50HZ,Three-phase five-wire system |

||||

|

|

|

|

|

|

|

|

|

|

Item |

HH-CP-3085 |

||||

|

KW |

Capacity |

850 |

||||

|

spm |

Slide stroke length |

40 |

50 |

60 |

70 |

80 |

|

mm |

Press speed |

120-200 |

120-180 |

120-160 |

80-120 |

80-120 |

|

mm |

Die height |

260-340 |

255-335 |

250-330 |

245-325 |

240-320 |

|

mm |

Throat depth |

350 |

||||

|

mm |

Bottom of slide size |

700 x 420 |

||||

|

mm |

Bolster size |

1000 x 700 |

||||

|

mm |

Height of collecting |

600 |

||||

|

mm |

Length of collecting |

1200/1500/2000 |

||||

|

mm |

Width of aluminum(max) |

330 |

||||

|

mm |

ID of aluminum |

Φ75/Φ150 |

||||

|

mm |

OD of aluminum |

Φ850 |

||||

|

KW |

Main motor |

7.5 |

||||

|

|

Supply voltage |

AC380V,50HZ,Three-phase five-wire system |

||||

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)