Emial Us :

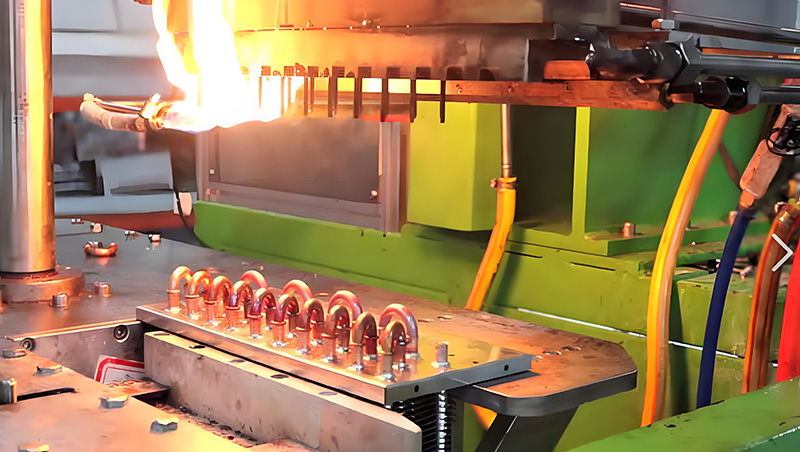

hongce@iectester.comThrough the automation of brazing process, the effective control of wire speed of the transmission line and the flame, and the effective control of gas flow, the welding temperature and the formation of solder fusing pool can be well controlled. To ensure the quality stability and consistency of welding. The digital control scheme provided by the equipment makes the process realization of the user very easy and reliable.

Item No :

HH-BZ-302Order(MOQ) :

1Payment :

T/T L/CProduct Origin :

ChinaColor :

Customizable colorsShipping Port :

Guangzhou PortLead Time :

30 working daysPrice :

NegotiatableFeatures of Automatic Brazing Machine:

The equipment is suitable for the heat exchanger of the mass flame brazing air conditioning system. After the operator has finished the preparation work, the brazing product is placed on the equipment conveyor belt. First, the protective nitrogen is filled into the product pipeline system, then the product advances with the conveyor belt.The products successively enter the preheating area of the flame, the welding area, the reduction area, and finally cool the workpiece with compressed air to complete the welding process.

|

Model |

HH-BZ-302 |

|

Main power supply |

3 phase 5 line AC 380 V,50HZ |

|

Use of gases |

oxygen, nitrogen, compressed air |

|

Air pressure |

5~7kgf/cm2 |

|

Nitrogen pressure |

3~5kgf/ cm2 |

|

Oxygen pressure |

3~7kgf/cm2 |

|

Water pressure |

1.0~2.0kgf/cm2 |

|

Fuel gas pressure |

0.8~1.2kgf/cm2 |

|

Ambient temperature |

—5℃~43℃ |

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)