Emial Us :

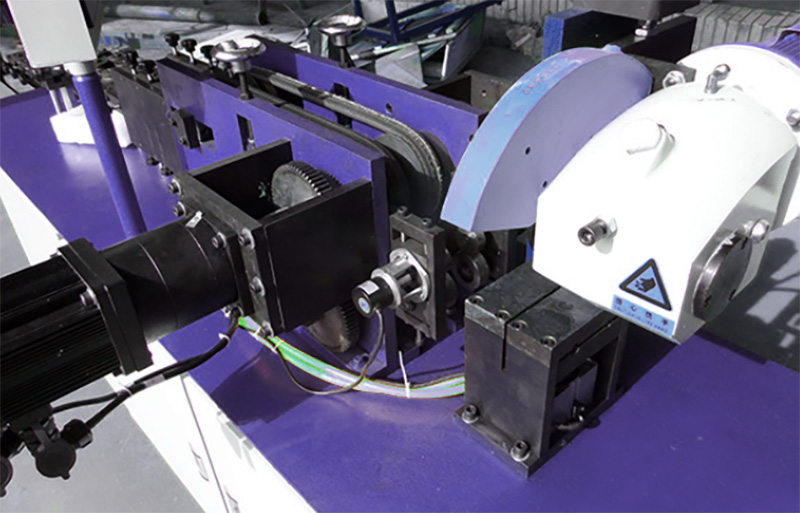

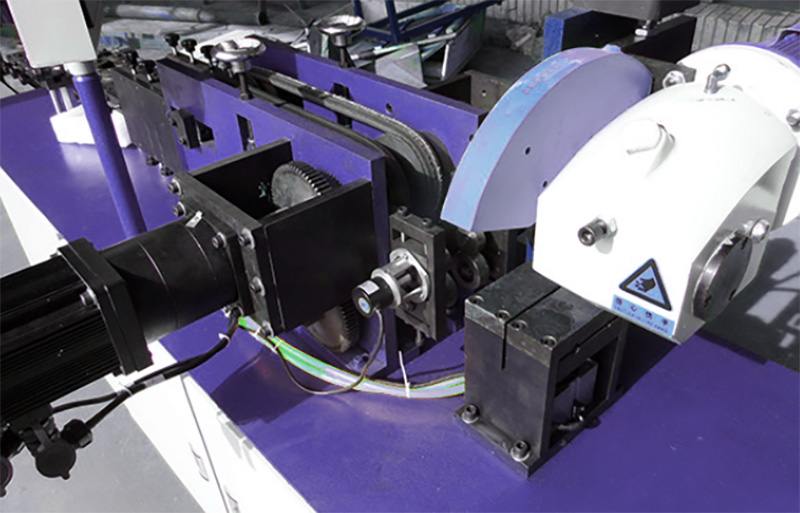

hongce@iectester.comCNC coiled pipe 2+2 chip-less 4-tube cutting-pipe end forming all-in-one machine is used to automatically uncoil, straighten, and chip-free fixed-length cutting of copper and aluminum coiled pipes, and fully automatic CNC shaping of the front and rear end pipe ends. Equipment to solve the problem of internal rotation and internal flanging. The equipment adopts CNC numerical control integrated control system for centralized control. It has USB copy and fault alarm functions. When a fault occurs, it directly displays the fault location, making troubleshooting convenient and simple. It can store more than 500 sets of product data.

Item No :

HH-KL-101Order(MOQ) :

1 setPayment :

T/T,L/CProduct Origin :

ChinaColor :

Customizable colorsShipping Port :

Guangzhou PortLead Time :

45 working daysPrice :

Negotiatable

|

Model |

|

|

Cutting pipe diameter |

Φ5-Φ19mm×1.5mm |

|

Processing object |

Copper and aluminum coil |

|

Maximum workpiece length |

1000mm can be extended (minimum processing length 150mm) |

|

Linear feed axis stroke |

0~800mm |

|

Linear feed speed |

0~1200mm/sec |

|

Linear feed accuracy |

±0.1mm |

|

Power |

Hydraulic, pneumatic mixing |

|

Minimum cutting length |

150mm |

|

Production cycle |

7-12 seconds (depending on the cutting length) |

|

Main machine dimensions |

3200X1000X1200 mm |

|

Power supply |

380V±10% 50HZ Three-phase four-wire |

|

Air source pressure |

0.4-0.8Mpa |

|

Total power |

7.5kw |

Integrated Functionality: It combines automatic uncoiling, straightening, and chip - free fixed - length cutting of copper and aluminum coiled pipes, along with the shaping of pipe ends.

CNC Control System: Equipped with a CNC numerical control integrated control system, it allows for centralized control. This system offers USB copy and fault alarm functions, enabling easy data management and quick troubleshooting. When a fault occurs, it directly displays the fault location, facilitating efficient maintenance.

High Precision: It is capable of achieving high precision in cutting and shaping operations. The linear feed axis has an accuracy of ±0.1mm, ensuring consistent and accurate production of components.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)