Emial Us :

hongce@iectester.comIn the refrigeration industry, long U tubes play a vital role as an important part of heat exchangers. They improve the efficiency and performance of refrigeration equipment by optimizing the heat exchange process. This article will explore the innovation and application of long U tubes in the refrigeration industry from the aspects of basic characteristics, production process, application fields and market trends.

Basic characteristics and production process of long U tubes

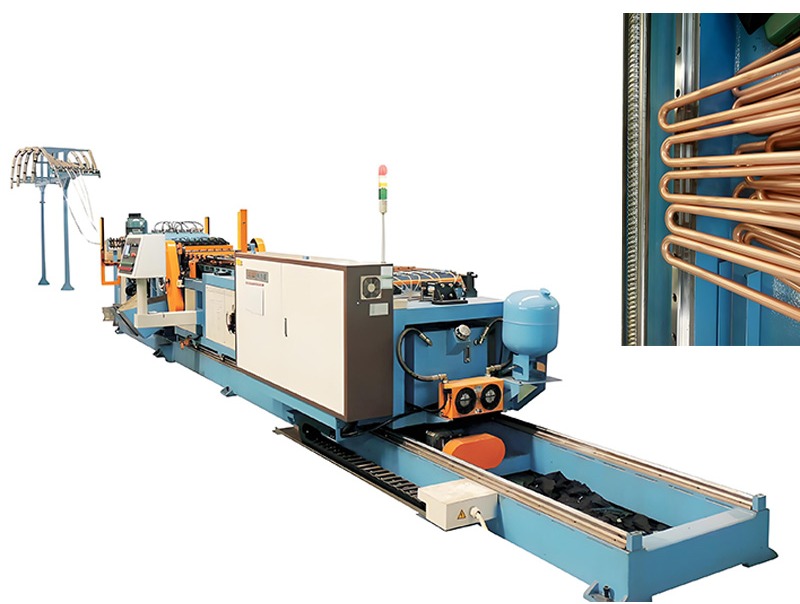

The long U tube, with its unique U-shaped design, increases the surface area of heat exchange, thereby improving the heat exchange efficiency. This kind of pipe is usually made of corrosion-resistant and high-strength materials such as stainless steel and copper to ensure its stability and durability in harsh refrigeration environments. During the production process, manufacturers use professional bending equipment (long U tube bending machine/hairpin pipe processing machine) to bend the material into a U shape and assemble it into a complete heat exchanger component through welding or connection technology. In this process, strict requirements for processing accuracy and quality control are essential to ensure that the long U tube can meet the design requirements and usage standards.

Application fields and market trends of long U tubes

Long U tubes are widely used in various refrigeration equipment, such as air conditioners, cold storage, refrigeration units, etc. They play a key role in heat exchange in these devices, helping the refrigerant to effectively transfer heat during evaporation and condensation. With the continuous development and innovation of refrigeration technology, the application areas of long U tubes are also expanding. Especially in high-tech fields such as new energy vehicles and aerospace, the quality and performance requirements of long U tubes are getting higher and higher. This has prompted manufacturers to continuously improve production processes and material selection to meet market demand. At the same time, with the improvement of environmental awareness, the manufacturing of long U tubes also pays more attention to environmental protection and sustainability.

Future Outlook and Summary of Long U Tubes

Looking to the future, the application prospects of long U tubes in the refrigeration industry are broad. With the continuous advancement of refrigeration technology and the continuous changes in the market, long U tubes will require higher quality and performance to meet new needs. Manufacturers need to pay close attention to market dynamics and technological developments, and continuously improve and innovate production processes and material selection. At the same time, users also need to regularly maintain and inspect long U tubes to ensure their normal operation and extend their service life. In short, as a key heat exchange component in the refrigeration industry, the innovation and application of long U tubes will continue to promote the development and progress of refrigeration technology. By continuously optimizing design and improving performance, long U tubes will bring more efficient, environmentally friendly and sustainable solutions to the refrigeration industry.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)