Emial Us :

hongce@iectester.comIn the modern refrigeration industry, fins are an essential component of refrigeration equipment, playing a critical role in the refrigeration process and overall performance of the equipment. To meet the growing demand for high-quality fins, the Fin Punch Press Machine has emerged as a highly effective production tool. This article provides a comprehensive analysis of the characteristics, advantages, and diverse applications of this innovative machine in the refrigeration industry.

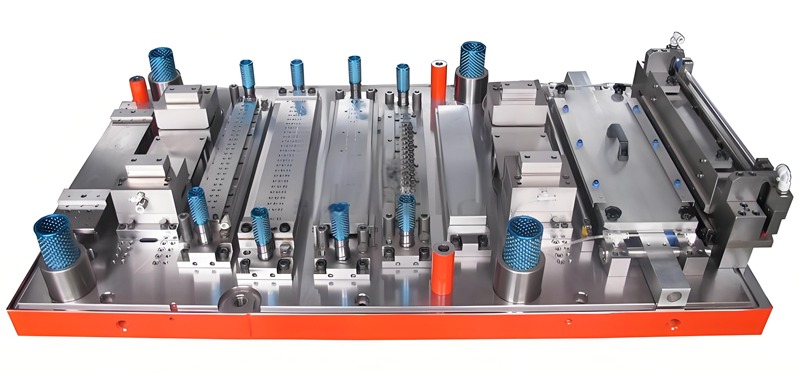

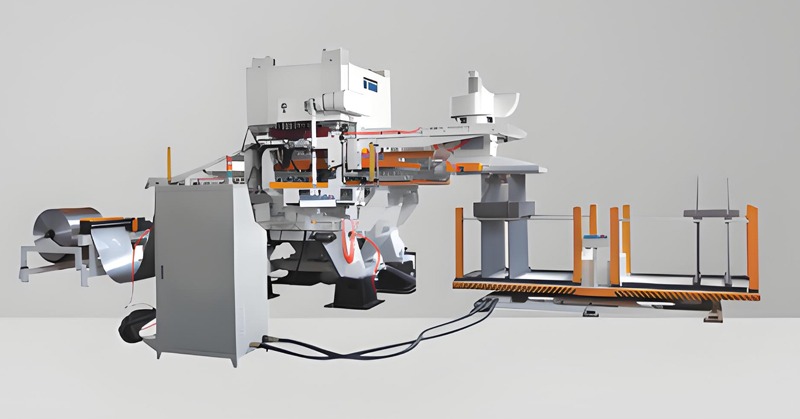

The Fin Punch Press Machine, or fin punching machine, is tailored for the production of fins within the refrigeration sector. It integrates high-speed, precise punching capabilities with automated components to deliver efficient, accurate, and stable fin production. The equipment encompasses a high-speed precision punching device, discharge rack, material handling mechanisms (including single and double jumps), material feeders, a collection system, electrical controls, and pneumatic systems, offering a comprehensive solution for fin manufacturing in the refrigeration industry.

As a high-performance production tool, the Fin Punch Press Machine boasts several standout features. Firstly, its high-speed punching technology ensures rapid production rates, enhancing overall efficiency. Secondly, the automated components minimize manual intervention, further boosting productivity. The machine employs high-precision molds and punching processes to guarantee the dimensional and shape accuracy of the fins, meeting the stringent quality standards required by refrigeration equipment.

The equipment's versatility is another notable feature. It can be configured with various functional components, such as material feeders and suction racks, to cater to different production needs. Custom designs are also available to suit specific customer requirements, providing a flexible production solution.

Safety and reliability are paramount in the operation of the Fin Punch Press Machine. It incorporates hydraulic overload protection to ensure safe shutdown in the event of anomalies, safeguarding both the equipment and operators. The machine uses PLC and a rotary encoder for centralized electrical control, ensuring the reliable operation of the automated production line. The compact design of the equipment facilitates easy maintenance and repair, and it is equipped with a quick mold change device for convenient mold replacement.

In terms of operation, the Fin Punch Press Machine offers seamless integration into the production process. Its advanced electrical control system ensures smooth and efficient operation, contributing to high levels of productivity. The machine's precise and consistent output ensures that the fins produced meet the strict specifications required for refrigeration equipment.

In summary, the Fin Punch Press Machine offers a combination of efficiency, precision, versatility, safety, and reliability in the production of refrigeration fins. It is not only an excellent choice for fin manufacturing in the refrigeration industry but also a driving force behind the industry's advancements in terms of production efficiency and quality. As the refrigeration industry continues to develop, the Fin Punch Press Machine will play a pivotal role in supporting the manufacturing of high-quality refrigeration equipment.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)